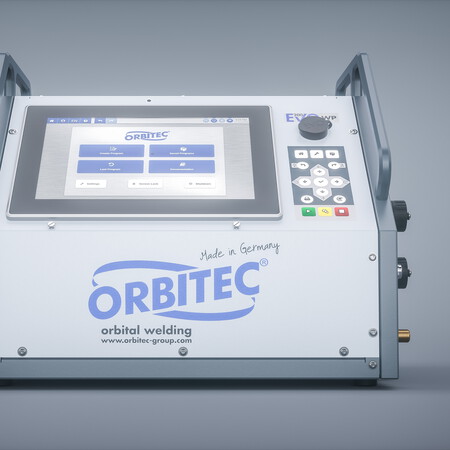

EVO 200 WP Orbital Welding Controllers

The EVO Industry 4.0 series is new to the market. Several systems, initially compact as the 200 A Autorange and now also modular in connection with the Tetrix inverters.

The systems are small, lightweight and handy and offer a high-resolution colour display, multilingual intuitive user guidance due to a colour touch interface, or alternatively operation using a membrane keyboard, a stable operating system (without data loss during power outages and quickly ready for use again), full access through tablet with QR-code scanner, data transfer via USB, LAN and WLAN, fault analysis program, manufacturer support via remote maintenance, a mountable cooling unit as an option, and many other functions.

Depending on the model, the systems are equipped with different features. Individual features can be added for a surcharge. The EVO 200 WP, for example, has an analogue Turbo Purge function as standard. When the Turbo Purge function is activated, before and after the welding process the cassette weld head is purged with an increased amount of gas (setting using the analogue knob on the controller and digital display).

Shortly before the welding process, the amount of gas is reduced to the amount required for the cassette weld head. This substantially shortens the welding process and achieves better welding results by precisely controlling the amount of gas.

In the case of the optional digital Turbo Purge function available for the EVO WP series, the gas flow is continuously measured and regulated by a gas flow controller. The amount of gas is set digitally on the display and saved in the program for future welding processes.

With the optional available Gas Controller Box, the Turbo Purge function can also be used with the EVO Modular WP.

During periods of high productivity, the cassette weld head can be preserved by activating the permanent gas function to extend the service life of the tungsten electrodes.

Technical data:

- Type of current DC

- Mains voltage AC 1 x 230 V +/- 15%

- AC 1 x 115 V +/- 15%

- Mains frequency 50 / 60 Hz

- Max. primary reserve power 6 kVA

- Rec. generator output 9 kVA

- Control range 5 – 200 A

- Welding current 25% ED TIG 200 A

- 60% ED TIG 150 A

- 100% ED TIG 120 A

- Weight: 16.8 kg

- Dimensions (L x W x H): 500 x 340 x 360 mm

Package includes:

- Orbital welding system

- Display transport protection

- Calibration certificate

- USB stick

EVO Series

EVO 200 WP (Autorange)

Technical specification:

- Current type: DC

- Mains voltage: AC 1 x 230 V ±15%

- AC 1 x 115 V ±15%

- Mains frequency: 50 / 60 Hz

- Primary maximum power: 6 kVA

- Recomm. generator output: 9 kVA

- Control range: 5 – 200 A

- Welding current: 25 % duty cycle TIG 200 A

- 60 % duty cycle 150 A

- 100 % duty cycle TIG 120 A

- Weight: 16.8 kg

- Dimensions (L x W x H): 500 x 340 x 360 mm

Scope of supply:

- Orbital welding system

- Display transport protection

- Calibration certificate

- USB flash drive

Item number: 1.3.7000

Accessories and extensions

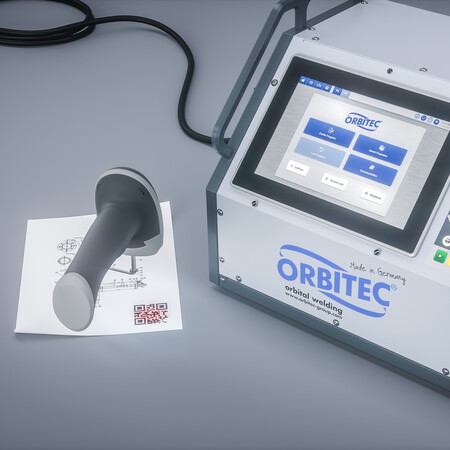

QR-Code Scanner

incl. software and QR code generator for PC for user login and accessing the welding programs

Item number: 1.3.7009

EVO Remote Control

via 10" industrial tablet with Scanner, Docking station and Backstrap

Robust 10" tablet as wireless remote control for all EVO orbital welding systems. The user interface of the EVO controller is mirrored 1:1, providing full access with all functions. As the data is sent over WLAN/LAN, there is no delay to the controls or display. The range complies with common WLAN/LAN standards and can therefore be easily amplified or extended. The tablet has an integrated 2D barcode or QR code scanner for user login and to access the welding programs. The tablet can be used as a mobile device and in the stationary docking station.

Technical data:

- Display: 10.1" (25.65 cm) capacitive touch display

- CPU: Intel® Atom™ with Intel® Burst Frequency technology Graphics card: GPU Intel® HD 400 Graphics

- Memory: 4 GB RAM, 64 GB eMMC

- Connections: WLAN, Bluetooth

- Scanner: 2D barcode scanner

- Ports: 1x USB 2.0, 1x micro USB 2.0, HDMI, audio, docking port

- Military standard: MIL-STD 810G

- Protection rating: IP65

- Battery life: Up to 8 hours Dimensions (L x W x H): 22 x 275.5 x 187.5 mm

- Weight: 1 kg Package includes

Tablet:

- Docking station

- Backstrap

- Power supply unit

Item number: 1.3.7010

Gas Controller Box

The Gas Controller Box enables to control up to three gases during welding and regulate them through the EVO WP controllers. The welding, the purging, and an additional gas (e.g., for a trailing nozzle, for flooding a gas cover or a housing) can be monitored, regulated, completely documented, and stored in the EVO controllers. All welding and purging gases that are used for TIG welding are memorized in the controller menu.

Technical Data:

- Control range: 1 – 54 l/min.

- Gases: Ar, He, N2, H2 (and mixed gases)

- Gas connection: 6 mm Push-In-Fitting in and out

- Weight: 0.9 kg

- Dimensions: (L x W x H) 180 x 220 x 100 mm

Package Includes:

- Water- and dustproof Peli case

- 1, 2 or 3 assembled mass flow controllers

- Connection cable Gas Controller Box / EVO WP controller

Gas Controller Box (1 Gas)

Item number: 1.3.7201

Item number: 1.3.7201

Gas Controller Box (2 Gases)

Item number: 1.3.7202

Item number: 1.3.7202

Gas Controller Box (3 Gases)

Item number: 1.3.7203

Item number: 1.3.7203

Spare longlife Paper Roll for EVO Controllers

Paper rolls for integrated printer, pack of three (shelf life: 10 years)

Item number: 1.3.0035

EVO Cool Water Cooling Unit (Autorange)

Water cooling unit for use with the EVO 200 WP or LITE controller and TETRIX 200 in conjunction with water-cooled welding tools.

- Standalone or continuous operation possible

- Temperature-regulated fan control

- Water flow feedback through in-built flowmeter

Package include:

- Water cooling unit

- Inverter / cooling unit (permanently mounted) connection cable

- Fasteners for EVO series

- 4 l blueCool 10i-5 coolant

Item number: 1.3.8000

Orbitcontrol 3 remote control

8-m cable remote control for all orbital welding controllers.

- Activate and deactivate the welding process

- Control the rotation

- Control the wire feed

- Control the AVC

- Visual status display

Item number: 1.3.0030

8 m cable remote control for all orbital controls.

Item number: 1.3.003003

GROUND CABLE 35 mm²

Lenght: 5 m / Size: 35 mm² / Voltage: up to 530 A

Item number: 1.3.0125

GROUND CABLE 50 mm²

Lenght: 5 m / Size: 50 mm² / Voltage: up to 500 A

Item number: 1.3.0146

GAS HOSE 3 m

Lenght 3 m

Item number: 1.3.0121

SPECIAL ARGON PRESSURE REGULATOR with triple flowmeters, brass

Pressure regulators with different connections and for use with other gas types / mixed or nickel-plated available on request.

Item number: 1.2.0134

0.5 – 10 BAR COMPRESSED AIR PRESSURE REGULATOR

incl. mounting bracket and inlet and outlet coupling (for RBK 60 S pneumatic connection). Pressure regulators with different connections and for other gas types or nickel-plated version available on request.

Item number: 1.2.0151

Switchbox

Switchbox for welding with two welding heads. To increase productivity, the switch box can be used to weid alternately in conjunction with a controller from the EVO series with two weid heads. All welding tools can be used, i.e., enclosed weid and open frame weid heads, turn tables or tube-to-tube sheet weid heads, gas or water cooled, with or without wire feed or AVC. By pressing the start button on the weid head, the welding program suitable for the respective weid head will get loaded. The weid head that is not being used is locked and can get prepared for the next welding.

Technical Data:

- Mains voltage 100-240V (0,6-0,3A)

- Mains frequency 50 / 60 Hz

- Switching capacity: 24V 200A (100% ED)

- Protection class: IP 23

- Dimensions: (L x W x H) 500 x 340 x 160 mm

- Weight 7.8 kg

Package includes:

- Switchbox

- Control cables, gas hose, welding cables from EVO series to Switchbox

Item number: 1.3.9000

200 / 10 BAR ARGON PRESSURE REGULATOR

(for RBK 60 S pneumatic connection)

Item number: 1.2.0150

Mobile orbital workstation

- Electrical supply integrated for auxiliary equipment: 5 x 230 V, 10 A (not suitable for the power source!)

- 2 steering castors, 160 mm diameter, with total lock

- 2 fixed castors, 280 mm diameter

- Extending cylinder holder with fastening chain above the centre of gravity of the cylinder

- High-quality powder coating

- Sturdy stainless steel worktop, folded edge

- Shelf for oxygen analyser

- Mount for bench vice with clamping prism

- Holder for open welding head

- Holder for manual hose package

- Space for inverter, cooling unit, etc.

Dimensions without holders installed:

1110 x 710 x 850 mm (L x W x H)

Weight: unloaded, approx. 70 kg

Mobile workstation

Item number: 1.2.0128

Item number: 1.2.0128

SPECIAL PRESSURE REGULATOR with twin flowmeter for H2 gases, brass

The cylinder pressure regulator with manual connection reduces the cylinder pressure of compressed gases and gases dissolved under pressure of max. 200 bar (300 bar on request) to a pressure corresponding to the flowmeter. The desired flow rate in l/min can be constantly set on the flowmeter.

Important: This pressure regulator has a constant working pressure of 2.5 bar to protect the orbital system’s gas flow sensor.

Control range:

- Twin flow 1 – 15 l/min, 3 – 25 l/min

- Triple flow 1 – 15 l/min, 3 – 25 l/min, 5 – 50 l/min

Item number: 1.2.0144

SPECIAL ARGON PRESSURE REGULATOR with twin flowmeter, brass

The cylinder pressure regulator with manual connection reduces the cylinder pressure of compressed gases and gases dissolved under pressure of max. 200 bar (300 bar on request) to a pressure corresponding to the flowmeter. The desired flow rate in l/min can be constantly set on the flowmeter.

Important: This pressure regulator has a constant working pressure of 2.5 bar to protect the orbital system’s gas flow sensor.

Control range:

- Twin flow 1 – 15 l/min, 3 – 25 l/min

- Triple flow 1 – 15 l/min, 3 – 25 l/min, 5 – 50 l/min

Item number: 1.2.0123

17 items