Quick change meets precision

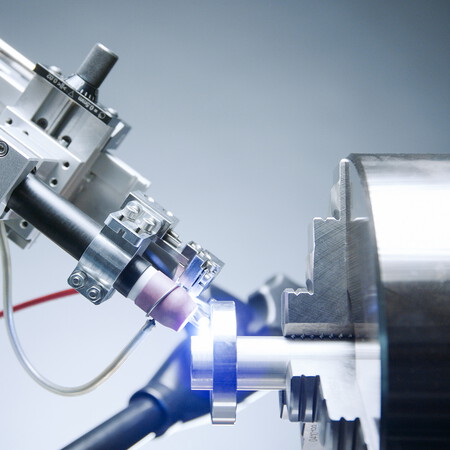

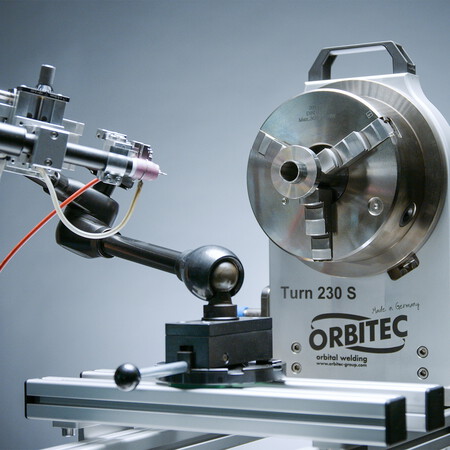

The Turn 230 S turntable features a quick change system that enables efficient processing of components with different tube diameters. The continuously swivelling arm and the hollow shaft, through which the inside of the component can be purged via the central axis, enable processing at the highest level. Its flexible adjustment options make the turntable the right solution for any component.

Everything a welding turntable must be able to do

- Securely hold non-standard components

- Rotate the workpiece around the torch for even distribution of welding energy and melt

- Precisely align the TIG torch with the component

- Process multiple workpieces with the same setup: high production speed with reduced welding defects

- Easy operation and high flexibility

- Robust and durable for industrial use

Turn 230 S turntable

Turn table, especially suitable for orbital components with higher quantities and can be connected to all Orbitec controllers.

Scope of application:

- Tube size range: OD 10 – 230 mm | 0.393 – 9.055"

- Max. load in horizontal position: 50 kg

Technical Data:

- Chuck: Three-jaw chuck with axis adjustment

- Swivel range: 0 – 90° stepless

- Power transmission: max. 300 A

- Weight: 88 kg

- Dimensions (L x W x H): 1.020 x 360 x 750 mm

Package includes:

- Turn table

- Three-jaw chuck

- Interchangeable jaws

- Chuck key

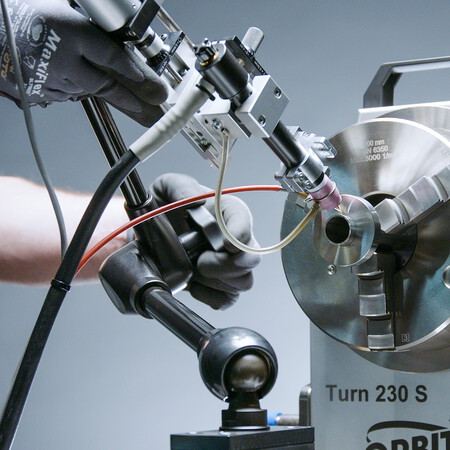

- Robust articulated arm with central mechanical clamping

- Ground cable

- Interconnection cable with wire and AVC outlet

Special versions available on request:

- Pneumatic torch adjustment

- Pneumatic centring and clamping

- Pneumatic tailstock

- Special diameters up to 1.000 mm

- Special lengths and complete workstation equipment available on request

- Special torch consumables

Item number: 1.2.1858

Accessories and extensions

To meet the high demands of orbital welding, we offer customized adaptations and various upgrade kits for the welding turntable Turn 230 S. On request, the torch can be mounted using a manual adjustment unit. Alternatively, the torch distance can be automatically set and adjusted via an arc voltage control (AVC). In addition, a cold wire feeder with different wire consoles can be integrated.

TURN 230 S machine torch with hose package 4 m

gas-cooled, equipped with torch consumables and tungsten electrode Ø 2.4 mm

ED: AC: 105 A, DC: 220 A, 60% (10 min.)

Special lengths and versions with a higher ED available on request.

Item number: 1.2.1814

TURN 230 S machine torch with hose package 4 m

gas-cooled, equipped with torch consumables and tungsten electrode Ø 2.4 mm

ED: AC: 105 A, DC:150 A, 60% (10 min.)

Special lengths and versions with a higher ED available on request.

Item number: 1.2.1814

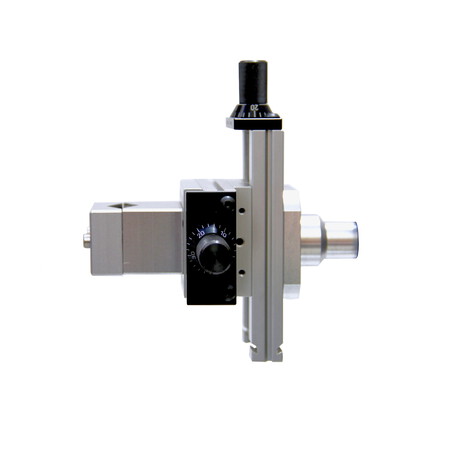

Manual adjustment unit for Turn 230 S using cross support

Slide width 50 mm, torch travel 50 mm, lateral adjustment 30 mm incl. torch clamp OD 20 mm incl. mounting flange

(Special torch clamp OD 30 mm available on request)

Item number: 1.2.1861

AVC unit assembly for Turn 230 S

incl. AVC motor with limit switching and 8 m connection cable, slide width 50 mm, torch travel 50 mm, lateral adjustment 30 mm incl. torch clamp OD 20 mm incl. mounting flange

(Special torch clamp OD 30 mm available on request)

Item number: 1.2.1859

Wire console for Turn 230 S

incl. wire outlet nozzle and three nozzle tips for 0.8 / 1.0 / 1.2 mm

Item number: 1.2.1852

Comfort wire console for Turn 230 S

(3D adjustable via linear unit)

Item number: 1.2.1869

Tube support for Turn 230 S

Item number: 1.2.1860

Clamp sleeve

OSW 40 CLAMP SLEEVE for torch, gas-cooled, Ø 1.6 mm, length 16 mm

Item number: 1.0.1616

Item number: 1.0.1616

OSW 40 CLAMP SLEEVE for torch, gas-cooled, Ø 2.4 mm, length 16 mm

Item number: 1.0.1623

Item number: 1.0.1623

OSW 40 CLAMP SLEEVE for torch, water-cooled, Ø 1.6 mm, length 17 mm

Item number: 1.0.1640

Item number: 1.0.1640

OSW 40 CLAMP SLEEVE for torch, water-cooled, Ø 2.4 mm, length 17 mm

Item number: 1.0.1641

Item number: 1.0.1641

OSW 80 – 275CLAMP SLEEVE, manual torch, Ø 1.6 mm

Item number: 1.0.1626

Item number: 1.0.1626

OSW 80 – 275 CLAMP SLEEVE, manual torch Ø 2.4 mm

Item number: 1.0.1627

Item number: 1.0.1627

CLAMP SLEEVE, TURN, Ø 1.6 mm

Item number: 1.0.1818

Item number: 1.0.1818

CLAMP SLEEVE, TURN, Ø 2.4 mm

Item number: 1.2.1819

Item number: 1.2.1819

CLAMP SLEEVE, RBK 60 S, Ø 2.4 mm

Item number: 1.3.3076

Item number: 1.3.3076

CLAMP SLEEVE, RBK 60 S, Ø 3.2 mm

Item number: 1.3.3089

Item number: 1.3.3089

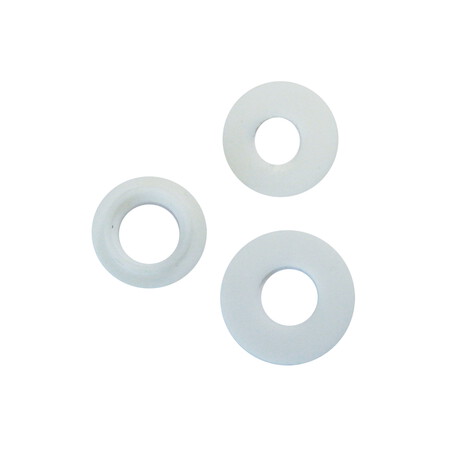

TEFLON INSULATORS

Teflon Insulator OSW 40

Item number: 1.0.1618

Item number: 1.0.1618

Teflon Insulator OSW 80 – 275

Item number: 1.0.1629

Item number: 1.0.1629

Teflon Insulator for Glass Gas Nozzle

Item number: 1.0.1051

Item number: 1.0.1051

Teflon Insulator TURN, Hand Torch

Item number: 1.2.1820

Item number: 1.2.1820

Teflon Insulator RBK 60 S

Item number: 1.3.3078

Item number: 1.3.3078

Gas lens OSW 40 Ø 1.6 mm

Item number: 1.0.1620

Item number: 1.0.1620

Gas lens OSW 40 Ø 2.4 mm

Item number: 1.0.1624

Item number: 1.0.1624

Gas lens OSW 80-275, TURN, hand torch Ø 1.6 mm

Item number: 1.0.1631

Item number: 1.0.1631

Gas lens OSW 80-275, TURN, hand torch Ø 2.4 mm

Item number: 1.0.1632

Item number: 1.0.1632

Gas lens for glass gas nozzle OSW 80-275, TURN, Ø 2.4 mm

Item number: 1.3.1049

Item number: 1.3.1049

Gas lens RBK 60 S Ø 2.4 mm

Item number: 1.3.3079

Item number: 1.3.3079

Gas lens RBK 60 S Ø 3.2 mm

Item number: 1.3.3096

Item number: 1.3.3096

Other gas cups available on request.

OSW 40 gas cup

Item number: 1.3.1046

Item number: 1.3.1046

OSW 80 – 275 gas cup, TURN, size 8

Item number: 1.3.1146

Item number: 1.3.1146

RBK 60 S gas cup, size 7

Item number: 1.3.3077

Item number: 1.3.3077

Gas cup, manual torch, size 6

Item number: 1.3.1911

Item number: 1.3.1911

TURN ignition aid, 15 mm diameter, 150 mm long

Item number: 1.2.1803

Item number: 1.2.1803

RBK 60 S ignition aid, TURN, 16 mm diameter, 180 mm long

Item number: 1.3.3088

Item number: 1.3.3088

RBK 60 S ignition aid, TURN, 24 mm diameter, 160 mm long

Item number: 1.3.3073

Item number: 1.3.3073

AVC Upgrade Kit for Tigtronic Controllers AVC Card for DC Motors Upgrade Kit (Turn)

for Tigtronic controllers

Item number: 1.3.0031

Torch caps

OSW 40 torch cap for water-cooled torch

Item number: 1.0.1615S

Item number: 1.0.1615S

OSW torch cap

Item number: 1.3.1147

Item number: 1.3.1147

TURN torch cap

Item number: 1.2.1817

Item number: 1.2.1817

Torch cap, manual torch

Item number: 1.3.1910

Item number: 1.3.1910

GAS LENS HOLDER

for glass gas nozzle

Item number: 1.0.1050

GLASS GAS NOZZLE

OSW 80-275, TURN

Item number: 1.3.1048

BURNER WEAR PART BOX GLASS GAS NOZZLE

1 burner cap

1 clamping sleeve

1 Teflon insulator

1 gas lens

1 gas lens holder

1 glass gas nozzle

Item number: 1.0.1052

Extension hose package, 8 m, gas-cooled

Item number: 1.3.2005

Extension hose package, 8 m, combined gas and water cooling

Item number: 1.3.2006

19 items