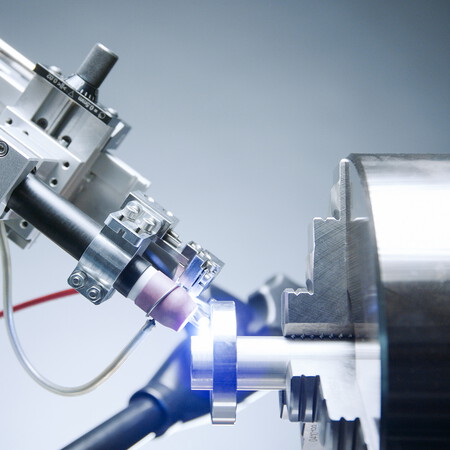

Orbital Welding System

Orbital welding is a complex process. We make your orbital welding tasks easier with innovative orbital welding systems. There are a number of different orbital welding systems, with modular or compact designs, tailored to suit different industry sectors and requirements.

An orbital welding system consists of several components: