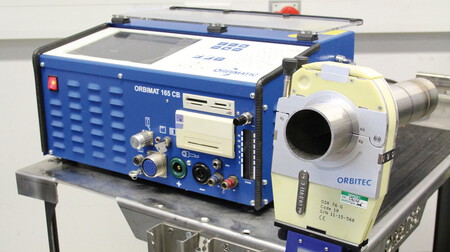

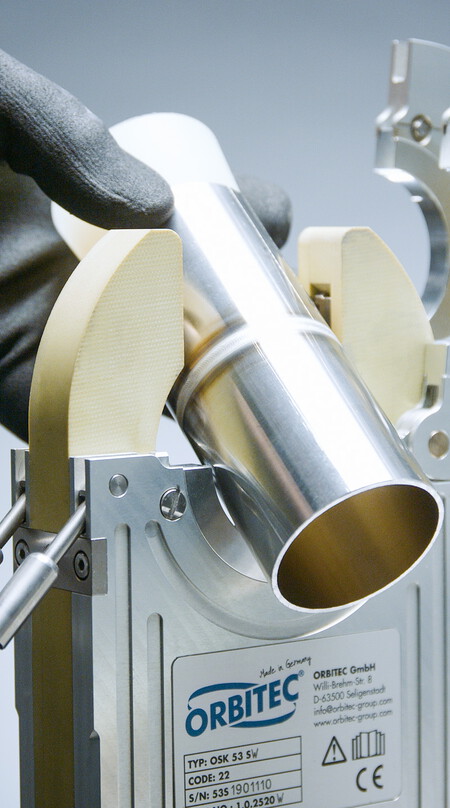

Orbital welding tools

Smart, flexible and absolutely precise: Every single welding device supplied by Orbitec is of the highest quality. Tools such as orbital welding heads impress with their precision. The variety of different product variants ensures that you can work with the correct system for each requirement.