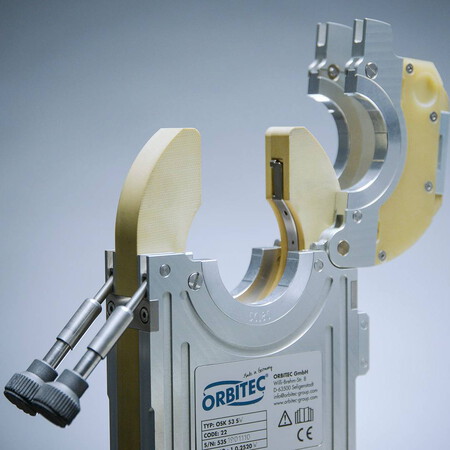

Enclosed Weld Heads

Our enclosed orbital welding heads stand for excellent welding results and maximum flexibility. Due to their design, enclosed orbital welding heads offer complete top layer protection of the weld thanks to continuous application of shielding gas during welding. This reduces the tempering colours of the welds. All Orbitec heads are available as water-cooled or gas-cooled designs and can be converted on request (except: microfitting welding heads).