Tube-To-Tube-Sheet Weld Heads

Tube-to-tubesheet welding heads make it possible to achieve consistently high-quality, reproducible welding of tubes to tubesheets. The use of filler wire and torch distance control via arc voltage control (AVC) is optional. The welding head is fasted in the tube in the tubesheet to generate a precise weld along the circumference of the tube. The tubes to be welded can be flush with the tubesheet, offset or protruding. The tube-to-tubesheet welding heads can be integrated into automated welding systems.

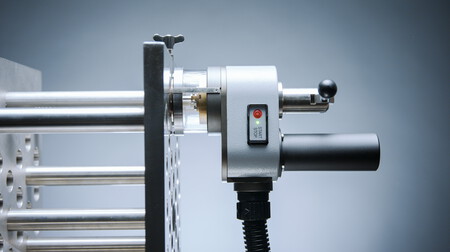

We offer special welding heads for welding tubes into tubesheets with orbital welding. The RBK 38 S is a small, handy welding head for welding in tubes with an ID of up to 36.7 mm, without filler wire. The highly robust RBK 60 S welding head is suitable for heat exchanger applications, optionally with arc distance control (AVC) and filler wire.