Orbital Welding Heads – Powerful, Space-Saving, Versatile

Our gas-cooled orbital welding heads are the perfect choice for classic cassette welding applications. Thanks to a well-designed interchangeable system, one drive unit is sufficient for different heads—efficient and economical. The portfolio is complemented by a micro fitting welding head with minimal space requirements and high thermal resilience—ideal for tight installation situations.

Exclusive at Orbitec: Flexible changeover system for orbital welding heads

By separating the drive unit, hose package, and welding head, a single drive unit can operate a variety of cassette welding heads (except for the microfitting welding head). This provides maximum flexibility while keeping costs low.

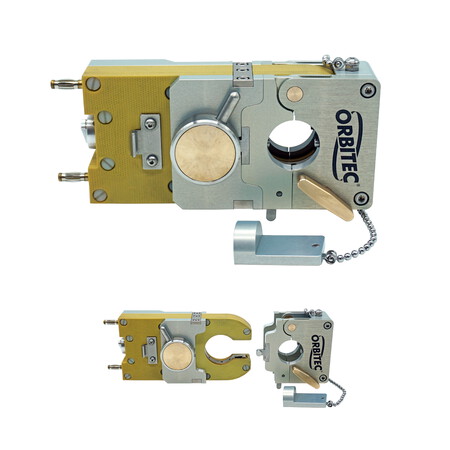

Micro fitting welding head OSK 13 S

Gas-cooled weld head for applications with extremely narrow space requirements, e.g. in the semiconductor industry. Specially designed to weld micro-fittings too. The design (specific gas flow management) and the material selection enable high thermal capacity, even without water cooling.

OSK 13 S

incl. handle and cable assembly, 6 m

- Extremely narrow / compact design.

- The head assembly is arranged in a way that makes it very easy to maintain.

- 6 m handle and cable assembly with practical handle (start/stop button and status display).

- Weld head compatible with 9-500 clamping cassettes from Arc Machines

Tube size range : OD 3,17 – 12,7 mm / 0,125″ – 0,500″

Weight: 2,4 kg

Item number: 1.3.4000

Accessories and extensions OSK 13 S

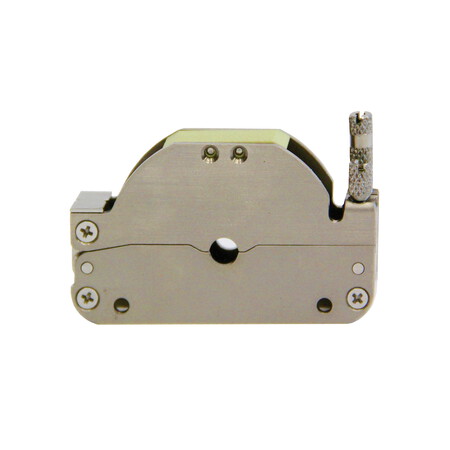

OSK 13 S Microfit clamping cassette

For welding where space is extremely tight

- Orbitec TCA clamping cassette, structural width 12 mm (0.472 inch)

- Clamping cassettes compatible with model 9-500 from Arc Machines

- Cassette can be mounted in both directions

Item number: 1.3.4001 + Ø

OSK 13 S Conversion Kit

Required for the use using clamping blocks

Item number: 1.3.4004

OSK 13 S Clamping Blocks for Tube-Tube connections

incl. setting gauge for tube

Item number: 1.3.4005

Collets for OSK 13 S Clamping Block

(1 set = 4 collets) incl. setting gauge for tungsten

Item number: 1.3.4006 + Ø

Fitting Mounting Kit for clamping Block OSK 13

Tube to tube clamping block needed

Item number: 1.3.4008 + Ø

OSK 13 S holder for work bench

Item number: 1.3.4022

OSK 13 S small tool kit

Scope of supply:

- Allen key set, 6 pieces

- Feeler gauge, 13 blades

- Tweezers

- Various screwdrivers

- Case

Item number: 1.2.0133

7 items

Gas-cooled weld heads OSK CS

Our new generation of two gas-cooled, compact weld heads that have been technically optimised and redesigned, for smaller nominal widths and featuring clamping levers. The heads were also designed for particularly tight space conditions with a narrow handle.

OSK 21 CS

Tube size range: OD 3,17 – 21,3 mm / 0,125“ – 0,839“

Weight: 0,8 kg

Item number: 1.0.2820

OSK 38 CS

Tube size range: OD 3,17 – 38,1 mm / 0,125″ – 1,500″

Weight: 1,3 kg

Item number: 1.0.2920

Gas-cooled weld heads OSK S

Our new generation of three gas-cooled weld heads that have been technically optimised and redesigned and have a tube size range of OD 6 – 114.3 mm / 0.250" – 4.500". Special design features and the material selection enable high thermal capacity, even without water cooling. The heads are even narrower and have a quick clamp system for the collets.

OSK 53 S

Tube size Range: OD 6 – 76,2 mm / 0,250″ – 3,000″

Weight: 2,6 kg

Item number: 1.0.2620

OSK 76 S

Tube size range: OD 6 – 76,2 mm / 0,250″ – 3,000″

Weight: 2,6 kg

Item number: 1.0.2620

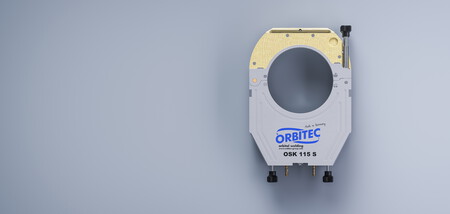

OSK 115 S

Tube size range: OD 9,53 – 114,3 mm / 0,375″ – 4,500″

Weight: 3,4 kg

Item number: 1.1.2720

Required Components

The following components are required to operate an OSK weld head. The drive unit houses the motor and the start-stop function for the weld head. Suitable clamping jaws ensure secure fixation and are selected according to the respective tube diameter.

OSK C handle and cable assembly, 8 m

Handle and cable assembly for OSK C and CS, consisting of a handle with control element (start/stop button and status display), weld head interface, motor / gearbox unit and 8 m hose package.

Item number: 1.3.2003

OSK G or S adapter flange to C or CS

Advantage: While using this flange, you can also use the OSK C and CS weld heads with the OSK G or S handle and cable assembly.

Item number: 1.3.2011

OSK S Drive unit

Handle and cable assemblies consisting of a handle with control element (start/stop button and status display), weld head interface, motor / gearbox unit and 8 m hose package. The OSK G and S handle and cable assemblies and weld heads are compatible with one another!

Item number: 1.3.2057

Collets OSK

We have a comprehensive range of collets in stock for all OSK heads. 1 set per tube outer diameter = 4 half-shells. All collet Ø in stock can be found in the table on page 66. Other Ø and collets with a common contact surface are available as custom designs on request.

Collets for OSK 21

Item number: 1.3.2321 + Ø

Item number: 1.3.2321 + Ø

Collets for OSK 38

Item number: 1.3.2021 + Ø

Item number: 1.3.2021 + Ø

Collets for OSK 53

Item number: 1.3.2521 + Ø

Item number: 1.3.2521 + Ø

Collets for OSK 76

Item number: 1.3.2621 + Ø

Item number: 1.3.2621 + Ø

Collets for OSK 115

Item number: 1.3.2721 + Ø

Item number: 1.3.2721 + Ø

Collets for OSK 170 HP

Item number: 1.3.2898 + Ø

Item number: 1.3.2898 + Ø

Collets for OSK 170 on 115

Item number: 1.1.28980

Item number: 1.1.28980

HP-COLLETS (OSK 53/76/115)

for optimising the tempering colours in clean rooms available on request.

Item number: on request

Chart for Tungsten Electrodes

SuperArc: Precision-machined disposable tungsten electrodes for reproducible orbital welding. Cut your costs, because each new manual sharpening operation costs time and money. Standard quality WC 20 to DIN EN ISO 6848.

Finished dimensions for all ORBITEC weld heads as a function of the tube outer diameter.

- Ø 1,0 mm, All lengths available, Ø Tip surface 0,1 mm, Polished section 30°

- Ø 1,6 mm, All lengths available, Ø Tip surface 0,2 mm, Polished section 18°

- Ø 2,4 mm, All lengths available, Ø Tip surface 0,4 mm, Polished section 30°

SuperArc tungsten electrode Ø 1.0 mm

Item number: 1.2.0202+mm

Item number: 1.2.0202+mm

SuperArc tungsten electrode Ø 1.6 mm

Item number: 1.2.0200+mm

Item number: 1.2.0200+mm

SuperArc tungsten electrode Ø 2.4 mm

Item number: 1.2.0201+mm

Item number: 1.2.0201+mm

Accessories and extensions

As a one-stop supplier for orbital welding, we also offer a wide range of accessories. Electrode holders and gas shield collets are available for the orbital welding heads. These are used to weld fittings, flanges and components with short welded sockets.

Offset Electrode Holder

from OSK 53

The weld head size’s maximum tube size range is then reduced.

for an electrode Ø OF 1.6 mm | 0.063"

Item number: 1.3.3106

Item number: 1.3.3106

for an electrode Ø OF 2.4 mm | 0.094"

Item number: 1.3.3101

Item number: 1.3.3101

Multi-position electrode holder

from OSK 53

The weld head size’s maximum tube size range is then reduced.

for an electrode Ø OF 1.6 mm | 0.063"

Item number: 1.3.3102

Item number: 1.3.3102

for an electrode Ø OF 2.4 mm | 0.094"

Item number: 1.3.3107

Item number: 1.3.3107

GAS-SHIELD BASE COLLET

GAS-shield collets are particularly narrow and have an aluminium base collet and a screw-on gas-shield collet made of heat-resistant GRP material. They are used to weld fittings, flanges and components with short welded hexagon nipples. In conjunction with offset or multi-position electrode holders, the weld can be completed very close to one side of the weld head. A collet set with a common contact surface is recommended for secure fixing. GAS-SHIELD collets are available for OSK 53 / 76 / 115 weld heads (the max. tube size range is limited).

GAS-SHIELD base collets and gas shields (1 set = 2 half-shells)

Gas-shield Base Collets for OSK 53

Item number: 1.2.3305

Item number: 1.2.3305

Gas-shield Base Collets for OSK 76

Item number: 1.2.3304

Item number: 1.2.3304

Gas-shield Base Collets for OSK 115

Item number: 1.2.3303

Item number: 1.2.3303

Gas shield collet (GRP)

(adaptation by the customer)

for OSK 53

Item number: 1.2.3308

Item number: 1.2.3308

for OSK 76

Item number: 1.2.3307

Item number: 1.2.3307

for OSK 115

Item number: 1.2.3306

Item number: 1.2.3306

Gas shield collet (GRP)

(prefabricated with through hole)

for OSK 53

Item number: 1.2.3309

Item number: 1.2.3309

for OSK 76

Item number: 1.2.3310

Item number: 1.2.3310

for OSK 115

Item number: 1.2.3311

Item number: 1.2.3311

OSK C, CS and CW holder for work bench

Item number: 1.0.5502

OSK S, SW and G holder for work bench

Item number: 1.0.5501

Extension hose package, 8 m, gas-cooled

Item number: 1.3.2005

Extension hose package, 8 m, combined gas and water cooling

Item number: 1.3.2006

OSK 21 CB gas-cooled weld head with clamping block for tube-to-tube connections

Weld head OSK 21 CB with eye & clamping screw, incl. setting gauge for pipe

Tube size range: DA 3,17 - 21,3 mm | 0,125“ - 0,839“

Weight: 1,0 kg

Item number: 1.0.28202

OSK 21/38 Tube Alignment Fixture

DA 6,35 - 25,40 mm | 0.250“ - 1.000“

Item number: 1.2.0154

S-TGS C or CL tungsten grinder

Portable tungsten grinders for precise and swift machining of tungsten electrodes for TIG orbital and manual welding.

- Fast & easy operation

- High precision and therefore reproducible

- Grinding in longitudinal direction

- A tip surface can be attached to the electrode.

- Fixed grinding angle

- Grinding without a collet

- Disconnecting of the electrode

- Alternatively as cordless or 230-V unit

- Both sides of the grinding wheel can be used

- Very lightweight and convenient

Scope of supply:

- Tungsten grinder

- Diamond grinding wheel

- T-handle hex key, 3 mm

- Transport case

- Charging cable (only for cordless unit)

Technical data S-TGS C // S-TGS CL

- Power: 170 W

- Mains connection: 220 – 240 V / 50 – 60 Hz // 10.8 V / 1 500 mA

- Speed: Adjustable between 8 000 and 35 000 rpm // 8 000 and 35 000 rpm

- Grinding angle: 15°, 18°, 22.5° and 30°

- Electrode diameter: 1.0 mm, 1.6 mm, 2.0 mm, 2.4 mm, 3.2 mm

- Diamond grinding wheel: 38 mm diam.

- Weight: 0.79 kg // 0.48 kg

S-TGS C

Item number: 1.1.0215

Item number: 1.1.0215

S-TGS CL

Item number: 1.1.0219

Item number: 1.1.0219

S-TGS diamond grinding wheel, medium grit

Can be used on both sides

Item number: 1.1.0216

Mobile orbital workstation

- Electrical supply integrated for auxiliary equipment: 5 x 230 V, 10 A (not suitable for the power source!)

- 2 steering castors, 160 mm diameter, with total lock

- 2 fixed castors, 280 mm diameter

- Extending cylinder holder with fastening chain above the centre of gravity of the cylinder

- High-quality powder coating

- Sturdy stainless steel worktop, folded edge

- Shelf for oxygen analyser

- Mount for bench vice with clamping prism

- Holder for open welding head

- Holder for manual hose package

- Space for inverter, cooling unit, etc.

Dimensions without holders installed:

1110 x 710 x 850 mm (L x W x H)

Weight: unloaded, approx. 70 kg

Mobile workstation

Item number: 1.2.0128

Item number: 1.2.0128

14 items